member

@ action

Rashin gazawar da Ball Screw ya haifar yana da bambanci daban-daban, babu wani daidaitaccen yanayi. Wasu rashin nasara ne a hankali rashin nasara, don samun wani ci gaban tsari, tare da amfani da lokaci kara girma; Wani lokaci kasawa ce ta ba zato ba tsammani, yawanci ba tare da alamun bayyane ba, kuma ba zato ba tsammani, wannan kasawa ta samo asali ne daga abubuwa daban-daban da kuma tasirin waje. Saboda haka, ta hanyar daidai ganowa don ƙayyade ainihin dalilin rashin aiki, shi ne sharuddan sauri da daidai gyara.

1) Ganowa da gyara na Ball Screw Nut mataimaki da kuma goyon bayan tsarin gap

Lokacin da CNC injin kayan aiki ya bayyana juyawa kuskure babban, matsayi daidaito rashin kwanciyar hankali, wuka alama ya bayyana a kan kwadrant, da farko don gano ko dunguwa tsarin da wani rabo. Hanyoyin ganowa sune: yin amfani da kashi na kashi tare da ƙarfe ball sanya a cikin tsakiyar rami na ƙarfe, auna axial motsi na ƙarfe, da kuma wani kashi na kashi don auna teburin motsi. Positive reverse juyawa dungulla, lura da darajar da aka nuna a kan kashi biyu, tabbatar da sassan gazawar bisa ga canje-canje daban-daban na darajar.

a) Ganowa da gyara na Screw goyon bayan bearing space

Kamar ma'aunin kashi na alamar a lokacin da alamar ba ta motsa lokacin da alamar ba ta motsa lokacin da alamar ba ta motsa lokacin da alamar ba ta motsa lokacin da alamar ba ta motsa lokacin da alamar ba ta motsa lokacin da alamar ba ta motsa lokacin da alamar ba ta motsa. Kamar kashi matakin nuna alama swing, nuna cewa Screw akwai motsi phenomenon. Babban bambanci tsakanin mafi girma da mafi ƙarancin ma'auni na kashi shine nesa na axial motsi na screw. A wannan lokacin, za mu duba ko baya cap na goyon bayan bearing kulle, ko goyon bayan bearing ya lalace, ko pre-load bearing gasket dace. Idan ba tare da matsala ba, kawai sake haɗuwa da shi a matsayin pre-load washer. Idan bearing lalacewa, bukatar a maye gurbin bearing, sake sanya a matsayin pre-load gasket, sa'an nan kuma sanya baya cap baya karfi. Girman sarrafa shaft motsi ya fi dacewa da daidaito na tallafawa bearing pre-load gasket. Mafi kyakkyawan yanayin madaidaiciyar shigarwa na dunƙule shine babu kyakkyawan rabo, goyon bayan bearing yana da yawan riba game da 0.02mm. b) Ganowa da kuma gyara na Ball Screw biyu Nuts Sub-samar da space

Ta hanyar ganowa, idan tabbatar da gazawar ba ta haifar da screw motsi. To, dole ne a yi la'akari da ko an samar da rami tsakanin yanayin walƙiya, hanyar ganowa ta wannan yanayin ta zama daidai da gano walƙiya. Ma'auna teburin da aka haɗa da walƙiya tare da kashi na kashi, juya walƙiya zuwa baya, gano mafi girman rata tsakanin walƙiya da walƙiya, sa'an nan kuma daidaitawa.

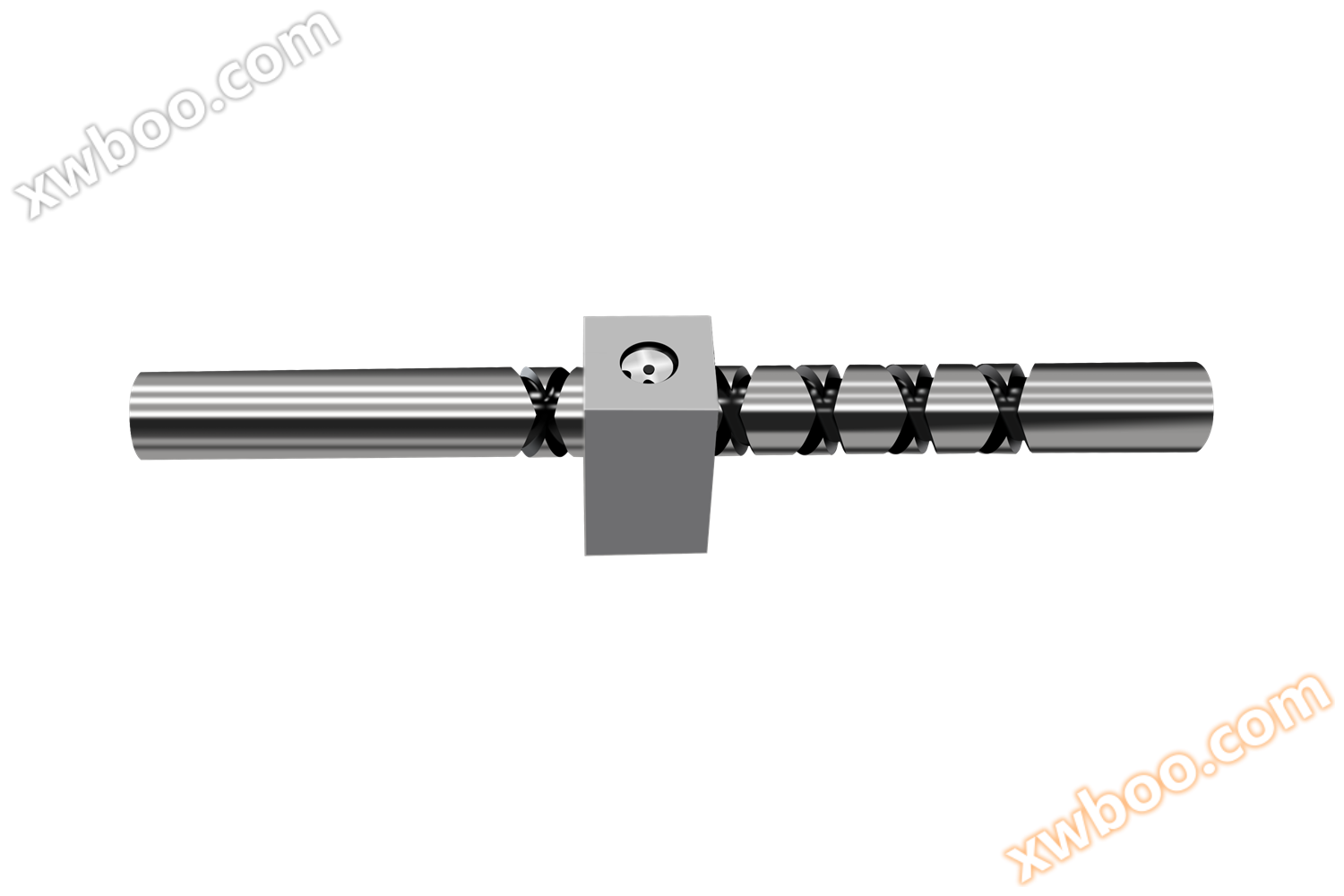

Hanyar kamar yadda aka nuna a Figure 2, daidaita kauri na gasket 4, don haka da hagu da dama biyu nuts 1, 2 samar da axial displacement, don haka kawar da ball dunƙule nuts gefen spacing da samar da pre-tensioning. Saboda tsarin mataimakin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙway

c) Ganowa da kuma gyara na guda nuts

Ga guda nuts Ball Screw, ba za a iya daidaita tsakanin Screw nuts mataimaki. Kamar gano wani rabo a cikin wani screw nuts. Da farko bincika ko an yi lalacewa da ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙway

Idan bincika lalacewa kadan, za a iya maye gurbin babban diamita ball don gyara. Da farko gano mafi girma rabo na rubutu nuts mataimaki, canza zuwa kara da ball diamita, sa'an nan kuma zaɓi dace ball re-assembly. Irin wannan gyaran ya fi rikitarwa, yana ɗaukar lokaci mai tsawo kuma yana buƙatar matakin fasaha mai girma.

d) Nut flange disk haɗi tare da teburin aiki ba tare da tabbatar da kyau da kuma samar da gap

Wannan matsalar gabaɗaya ne mai sauƙi a watsi da shi, saboda dogon lokaci na injin kayan aiki motsi da kuma zuwa, tabbatar da farat disk da dungulla lafiya samar da rata, a lokacin duba dungulla kwakwalwan kwakwalwan kwakwalwan kwakwalwan kwakwalwan kwakwalwan kwakwalwan kwakwalwan kwakwalwan kwakwalwan kwakwalwan kwakwalwan kwakwalwan kwakwalwan kwakwalw

e) Ball dunƙule nuts m motsi, amo da sauran lalacewa gyara.

Ball dunƙule ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙwayoyin ƙ

2) Bearing, madaidaicin lubrication na duniya

Kayan aiki na inji a aiki kamar samar da amo da rawar jiki, bayan gano babu matsala a cikin sassan inji, da farko dole ne a yi la'akari da matsalar rashin lubrication, da yawa kayan aiki na inji bayan shekaru da yawa na aiki, dunguwa walƙiya atomatik lubrication tsarin sau da yawa toshe, ba zai iya lubricating ta atomatik ba. Za a iya ƙara high zafin jiki juriya, high gudun juriya grease a bearings, nuts za a iya magance matsalar. Lubricating mai zai iya tabbatar da bearings, nuts aiki daidai shekaru.

3) Matsalolin tuki na servo motor

Wasu kayan aiki na inji a cikin motsi samar da rawar jiki da crawling, sau da yawa gano sassan inji ba tare da matsala ba, ko ta yaya daidaitawa ba za ta kawar da rawar jiki da crawling ba. Bayan dubawa mai kyau, an gano cewa sigogin karɓar servo motor ba su dace da ainihin yanayin aiki ba. Bayan daidaita samun sigogi, za a iya kawar da rawar jiki da crawling.

QNetworkAccessFileBackend